Because each transition can be applied quickly and easily, screen print copies have proven quite famous in the creative group. The technique for making a one-color transference is straightforward. Multiple hues add complexity to the situation. How to make full color screen print transfers? We’re here now to investigate it.

Screen Print Transfers: What Are They?

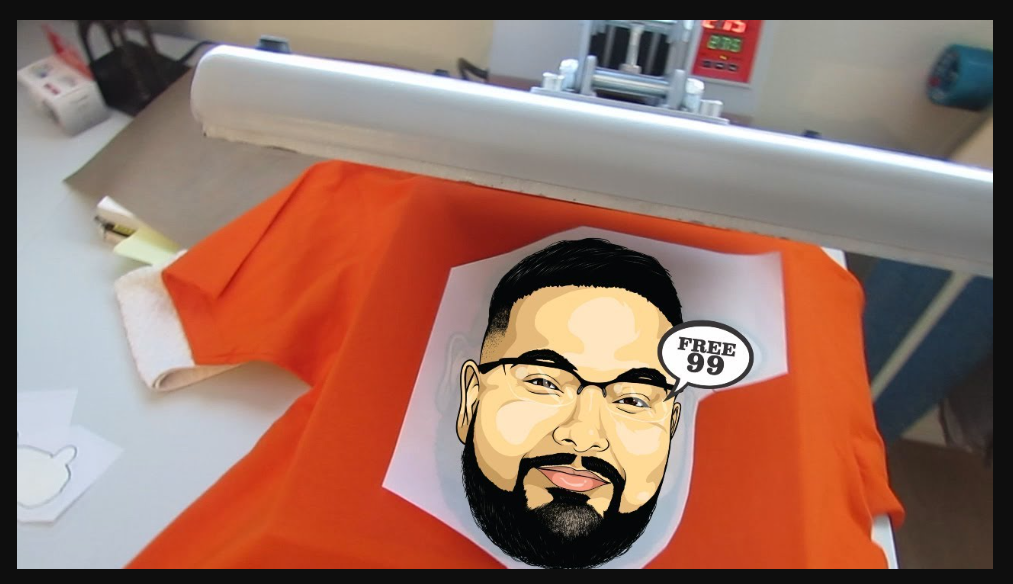

On a specific type of releasing or transferring paper, patterns are screens imprinted in reverse. Intense heat is applied to the sheet after it has been placed ink piece down just on a receptive surface, for example, a t-shirt, which enables the print to move out from the sheet to the cloth.

Screen print conversions come in a variety of forms. Screen printing a pattern with plastisol dye onto the raised surface is among the most used methods. Using dispersion dyes to produce a sublimated print is another common technique for producing this print transference.

In most cases, designing and producing a print transfer is similar to producing the print directly on a garment or other material. The advantage of employing a transfer is that you may create several copies of a single image simultaneously and store them for future use. Additionally, you may charge them for the option of subsequently applying the transference on any surface.

Screen print transactions: how are they done?

Making screen print conversions is an easy procedure that may be a good option for business operators trying to grow their clientele and boost revenues.

Procedure for transferring screen prints

- It’s important to have proper screen tension while publishing onto paper. Utilize between 8 and 16 inches of off-contact space to allow the screening mesh to discharge ink over onto transference paper.

- Use moderate pressure as well as saturate the area with one squeegee stroke at a scraper inclination of 70 to 75 degrees. Following publishing, allow the ink to escape.

- The dye should be flash-cured between 180 and 260 degrees Fahrenheit; need not permit the temperature to exceed 280 degrees, or even the paint could over-cure.

- With designs with many colors, write the last color while the ink is still damp to provide a surface for the sticky glue to adhere to. When the sticky powder is full time to adhere to the pigment ink, pour over the sheet inside an open container, cascading it across the entire portion, and then tap off from the surplus material.

- When putting it into the machine, ensure the transferring ink reaches a temperature of 275 ℉ so that it can gel. When it’s too warm, the pattern won’t transfer to the clothing.

- Inspect the paper again to ensure no unintentional marks that might migrate towards the shirt before the print transference is prepared to be heat ironed. If so, remove these.

- Strip away the transference sheets after heating that in the thermal pressing for 10 to 12 moments at 330 ℉ using moderate pressure to show a stunning print.

- Similar to screen printing, employing light-colored clothing requires something under the undercoat as opposed to a darker-colored garment requires a printed, flash, and print underneath the undercoat.

Full Color Transfer: What Is It?

Screen printing and DTG are alternatives for short runs that can be used instead of color image digital transference. Although it doesn’t need a full screen mode setup, the colors are still brilliant, like screen printing.

Are full-color screens printed possible?

Whenever screening publishing full-color graphics on clothing, there have been two primary printing choices: full-color process painting (also known as CMYK) as well as simulating process publishing.

What is the process?

Using an inkjet printer using CMYK-W ink and powdery plastisol dye, a design is generated. The fabric or foundation is then covered with the pattern and allowed to cure. There are instances when a pattern is imprinted onto film as well as the overall product is copied, and there are instances where each color is sliced and placed individually.

How To Convert A Canon Printer To Sublimation?

Batik Institute

How to make full color screen print transfers?

Using a DTG or sublimated printer is the most straightforward approach to producing full-color copies. Both methods have advantages and disadvantages. Only after utilizing color separation software and making light exposure stencils for every color could you make full-color pictures with digital printing.

Advantages

The ability to use a sublimated printer to generate hues using a digital CMYK system is the main benefit of employing a sublimated transference for a color image artwork. When you utilize sublimation publishing, the printer combines all the hues and tints to make a copy of the picture for yourself!

To just about any artificial cloth or a hard object coated with synthetic fibers, sublimated copies are simple to use. Additionally, full-color sublimated transferring prints are rather simple to make.

Disadvantages

The fact that sublimated patches can only be used on cotton t-shirts is their major drawback. They cannot be applied to cotton. Additionally, you must have a sublimated printer. To ensure that your sublimation prints adhere to polyesters, utilize sublimated paper as well as the appropriate sublimated dyes.

Sadly, even though DTG printers are expensive, they are still the greatest option for printing DTG/DTF conversions. The dye used in these printing is water-soluble and meant to seep through into fabric instead of remaining on the outside. You may utilize DTG printing to generate color image graphics onto special paper when you have a competitive setting or want to start your own company.

What would you require while considering ‘How to Make Full Color Screen Print Transfers?’

Prior to moving on to manufacturing, you’ll use a few items because manufacturing heat transfer rate is a distinct procedure from publishing on t-shirts. In addition to transferring paper, a thermal press, a workshop vac, as well as transferring adhesive powder, you will also need these items.

How to make full color screen print transfers? Steps

- Make a sublimated transferring print using these procedures.

- An electronic design should be prepared first. Prior to printing, please be careful to turn the picture horizontally and duplicate it.

- The written side should be down as well as the matte texture side should be up when inserting the sublimated transfer paper into printers.

- The design can be printed. Refrain from being concerned if it seems darker than the computer fabrication.

That’s all, then!

Although producing the sublimated transfer itself doesn’t involve much labor, applying it to a t-shirt subsequently does take a heat press.

How much should I charge for custom vinyl shirts?

Batik Institute

FAQs.

How do DTF as well as screen printing vary from one another?

Another choice is publishing that is done directly on clothing or DTG. DTG, as the name indicates, involves applying ink instead of screening straight to a garment. DTG employs lighter, water-based dyes instead of the heavy ink used in digital printing. The pattern is woven into the cloth using the DTF method.

Why would CMYK seem flat on display?

Colors onstage may not be accurately replicated using CMYK printing, which is why they appear differently offscreen. These hues are referred to as “out of gamut.” Dazzling and vivid hues are two examples. Compared to CMYK, the RGB color spectrum contains a far wider variety of colors.

Do CMYK prints have a brighter appearance?

Utilizing a combination of these four hues in various ratios, this color scheme is utilized to produce printed graphics. Contrary to RGB, the CMYK color system subtracts light from or absorbs it when hues are blended, resulting in darker hues rather than brighter ones.

How can I make my colored prints seem better?

Purchase premium ink.

Make adjustments to the resolution.

Finish cleaning and aligning the printer heads.

Make use of sturdy paper.

Think about calibrating the display.

Switch to the printed setting