Due to their non-breathable features, acrylic fabrics are very popular for making winter clothes.

But can you sublimate on acrylic fabrics?

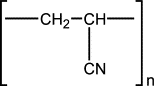

Yes, you can sublimate on acrylic fabrics. Acrylic fabrics are made from polyacrylonitrile, which is a polymer. Polyacrylonitrile bonds with the sublimation ink and absorbs it, and as a result, sublimation works great on acrylic fabrics. Also, because of the high polymer count, the acrylic fabric does not need any additional polymer coating. That’s why it’s also possible to sublimate on 100% pure acrylic.

In the upcoming sections, you will get to know the details of sublimation printing on acrylic fabrics.

Can You Sublimate On Acrylic Fabric?

Acrylic fabrics are great for sublimation compared to other natural and synthetic fabrics for a number of reasons. Let’s see what makes acrylic fabrics suitable for sublimation printing.

Raw Material:

Acrylic fibers are made from polyacrylonitrile, which is a synthetic polymer. That’s why acrylic fabrics have a high polymer content. For a fabric to be called “acrylic,” it has to contain at least 85% acrylonitrile. The remaining 15% of the acrylic fabric is usually vinyl acetate or methyl acrylate, which are also types of polymers.

High-polymer contents have multiple benefits for sublimation printing. During the printing process, the sublimation ink is heated and turned into gas. At the same time, the heat causes the fibers to open up and allow the gas inside.

When the ink and the fabric cool down, the fibers tighten and the gas solidifies. This creates a bond between the fabric and the ink on a molecular level. Due to this bond, the ink becomes resistant to fading, making acrylic fabrics a popular choice for sublimation.

A polymer coating is added for additional benefits in natural or other fabric blends with low polymer content. Since the acrylic fabric is literally made from polymer, you do not need to add a coating to it.

Heat Resistant:

Acrylic fabrics have a higher melting point compared to other synthetic fabrics. The acrylic fabric has a melting point of 215-255 degrees Celsius, and the heat applied during the sublimation process is around 180–200 degrees Celsius.

This means that when heat is applied during the heat-pressing process, the fabric will not melt or deform, making it ideal for sublimation.

Let’s look at a comparison of melting points between different synthetic fabrics.

| Synthetic Fabric | Melting Point |

| Acrylic | 215-255°C |

| Nylon 6 | 215-265°C |

| Nylon 66 | 295-300°C |

| Polyester | 295-300°C |

| Polyethylene | 110-135°C |

| Polypropylene | 130-170°C |

| Polyurethane | 160-180°C |

| Rayon | 125-150°C |

| Spandex | 240-250°C |

Since, nylon is also a synthetic fabric with a high melting point, you can also sublimate on nylon fabrics.

Shrink Resistant:

Acrylic fibers have a low moisture absorption rate, which means they are less likely to become distorted when exposed to water. That’s why they’re highly resistant to shrinking.

Furthermore, acrylic fibers are thermoplastic and elastic, so they can withstand repeated washings and wears without losing their shape or size. The combination of acrylic’s low moisture absorption, thermoplastic properties, and good elasticity makes it a very shrink-resistant material, making it popular for sublimation.

Raw Color:

The raw color of the fiber is important for the sublimation process; otherwise, the fabric won’t be able to produce a vibrant end result after printing. The color of undyed acrylic fiber is raw white, which is ideal for sublimation.

The raw white color of the fiber can hold the color very well, making it possible to print complex color compositions in detail.

But acrylic fibers are also available in different colors if the manufacturer decides to add color. But the raw color of the fibers is ideal for sublimation.

Because of these sublimation-friendly properties, you can sublimate on acrylic fabric. But can you sublimate on 100% acrylic fabric?

Yes, it’s possible to sublimate on 100% acrylic fabric because acrylic fibers are made from polyacrylonitrile, which bonds with the sublimation ink. Also, naturally, acrylic fabrics have a higher melting point. That’s why there is no need to add extra polymer to make it heat resistant or susceptible to sublimation ink, making it suitable to sublimate on 100% acrylic.

Types of Acrylic Fabric: Which One Should You Go For?

Among all the different types of acrylic fabrics, standard acrylic is the most suitable for sublimation printing. Standard acrylic fabrics are more heat and chemical resistant compared to other types of pure and blended acrylic fabrics. This makes it the ideal choice for sublimation printing.

There are four types of acrylic fabrics: standard acrylic, modacrylic, lastrile, and nitrile. Here is a short comparison between these four variations to find the best one for sublimation.

| Name | Material Composition | Melting Point |

| Acrylic | 85% polyacrylonitrile, 15% vinyl acetate or methy acrylate | 215-255°C |

| Modacrylic | 30-80% polyacrylonitrile, with vinyl chloride, vinylidene chloride or vinyl bromide | 120-130°C |

| Lastrile | 10%-50% acrylonitrile with butadiene | 200-220°C |

| Nitrile | 85% vinylidene dinitrile, 15% vinyl acetate | 120-140°C |

From this table, it’s clear that standard acrylic fabric is the best for sublimation as it has more polyacrylonitrile, which helps absorb the ink. On top of that, the fibers have a high melting point, making them perfect for the heat transfer process.

How to Use Acrylic Fabric for Sublimation?

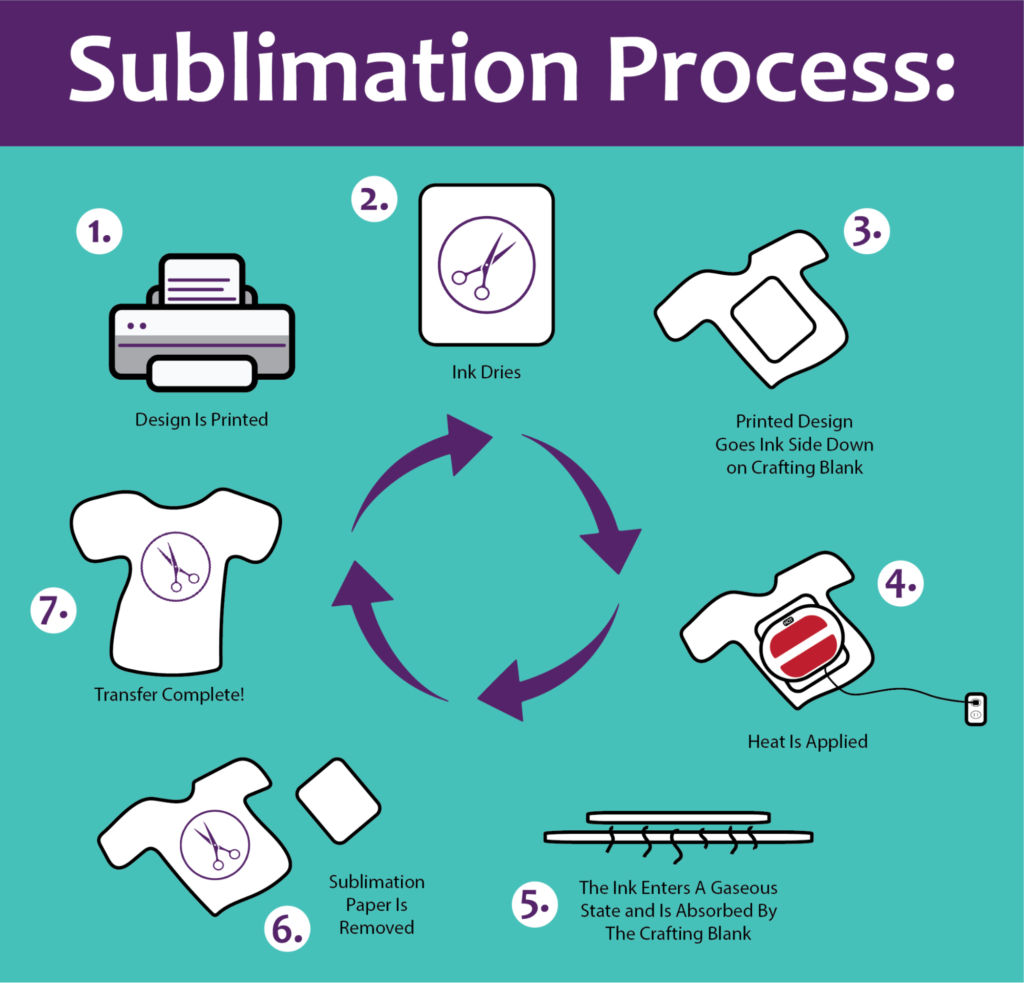

The basic sublimation process is to choose the design you want to print and print it on the sublimation paper using the printer. Then use the heat press machine to transfer the design to the fabric.

It sure does seem simple, but there are some complications. You need to be precise with the process. So, here is a detailed process for sublimating on acrylic paper.

Tools Needed:

- Sublimation Printer and Ink ( you can convert regular printer for sublimation too)

- Sublimation Paper

- Heat Press Machine

- Heat Tape

- Butcher Paper

Step One: Create Your Design

First things first, you need to create the design you want to sublimate. There are numerous software programs available to you. For example, Adobe Photoshop, Canva, etc.

Step Two: Print Your Design

The next step would be to print the design onto the sublimation paper. To print a design on sublimation paper, first, create or select a design using graphic design software.

Then, mirror the image horizontally to ensure it will be correctly oriented when transferred. Next, load the sublimation paper into your printer and print the design onto it using sublimation ink.

To get the best results, you must use a printer, ink, and paper designed for sublimation.

Step Three: Heat Transfer

This is the most crucial part of the sublimation process. You will need to place the sublimation paper (print side down) on top of the fabric. Then use the heat press machine to press the paper onto the fabric. Doing this will transfer the print onto the fabric.

The process is delicate because you will have to be precise with the heat press machine. A slight disturbance can adversely affect the print. So, knowing how to use a heat press machine is a must.

Things to Consider While Sublimating on Acrylic

There are three things that you must keep in the back of your mind while sublimating on acrylic fabric. All three are crucial to the process, and a slight change in any one of them can ruin the print. The three things are time, temperature, and pressure.

Time:

First, let’s discuss how long to sublimate on acrylic fabric.

Acrylic fabrics can deal well with heat, but you still need to be precise with your timing. Usually, the ideal time to keep the heat press running is for 45–60 seconds.

Temperature:

Up next is the temperature required for the sublimation process on acrylic. The optimum temperature of the heat press should be between 370 and 400 degrees Fahrenheit (188 to 205 degrees Celsius).

One crucial tip I want to mention here is that you better warm up the machine beforehand, and you should also warm up the non-printing side of the fabric. This is to make sure the fabric doesn’t bend from the sudden application of heat and pressure.

Pressure:

So, sublimation on acrylic time and temp is all sorted out. Now, what about the pressure?

The pressure required to sublimate on acrylic fabric should be around 30 to 40 psi, but there are no pressure gauges or meters with the machine. So, you will have to apply low to medium pressure by hand.

Before using the heat press, use the heat tape to adhere the paper design side to the fabric’s printing side. Ensure the image is at the right angle and isn’t moving around by sealing it neatly.

If you have followed the instructions properly, the sublimation process should be done by now. Finish the process by removing the fabric from the heat press and letting it cool off. Also, remove the heat tape and sublimation paper.

How to Fix Sublimation Paper Sticking to Acrylic Fabric?

To fix sublimation paper sticking to the acrylic fabric, you can apply a bit of water to the paper to remove it.

If that still doesn’t work, wait until the fabric has cooled off, then soak it in water for a couple of minutes. This should get the paper out of the fabric. Also, you can try to remove the paper using a magic eraser.

Tips for Getting the Best Sublimation Print on Acrylic Fabric

The sublimation process may seem very simple and straightforward in theory, but in reality, it could get really complicated. So, here are some tips for the best possible results.

- Save the design in the correct format and resolution. The file types best for sublimation are PNG, JPEG, SVG, PDF, PSD, EPS, and TIFF. Also, the resolution should at least be 300 DPI.

- Make sure to print on the correct side of the sublimation paper.

- Do not sublimate on a fabric that is dirty. Always check if the fabric is clean.

- Use the heat tape properly so that the paper doesn’t move.

- It’s better to pre-press the fabric to get all the moisture out. This will prevent small dots from being printed due to moisture. Apply heat to the fabric before the actual process. The pre-press heat should be slightly lower than the actual transfer temperature.

- It’s always a good idea to test a small area of the fabric first before committing to a full transfer. This will help you determine the best settings for the particular fabric and transfer paper being used.

If you tried sublimating on acrylic fabric but it didn’t turn out too well, don’t worry. You can easily fix some sublimation mistakes.

Frequently Asked Questions (FAQs):

Which designs work well on acrylic fabric?

Acrylic fabric is great for designs with vibrant colors, intricate details, and photographic images. The process allows for a wide range of colors and shades to be used, producing a high-quality print that is sure to grab attention.

Can you heat press 100% acrylic?

Yes, you can heat press 100% acrylic. Acrylic is made from polymers, so it retains heat well. While acrylic fibers can retain heat well, it’s important to use caution when heat pressing 100% acrylic, as the fabric can melt or become distorted under high heat.

What fabric is best for sublimation?

The best fabric for sublimation is polyester or polyester-blend blends. This is because sublimation ink is designed to bond with the polyester fibers at a molecular level, resulting in a vibrant and long-lasting image. The higher the polyester content, the brighter and more vivid the colors will appear after sublimation.

Conclusion

So, can you sublimate on acrylic fabric? Yes, you can, but using the right procedure is crucial. Applying too much heat and/or pressure can distort the fabric and the print, and applying too little won’t be enough to transfer the print onto the fabric.

To figure out the optimal requirements, it’s necessary to experiment with the heat, pressure, and timing. In addition to that, using a high-quality printer, ink, and paper is also vital for getting the best possible print.