We frequently receive inquiries like this since there are several specialized paper subcategories available for purchase, as well as countless tasks that can be completed with them. Is there a heat transfer paper that doesn’t need cutting? Which type of thermal transfer paper would I require?

Quick Response

Is there a heat transfer paper that doesn’t need cutting? Currently, there are no self-weeding inkjet transferring sheets available right now. Therefore, there is no heat transfer paper that doesn’t need cutting.

How does a thermal sheet that “self-weeds” work?

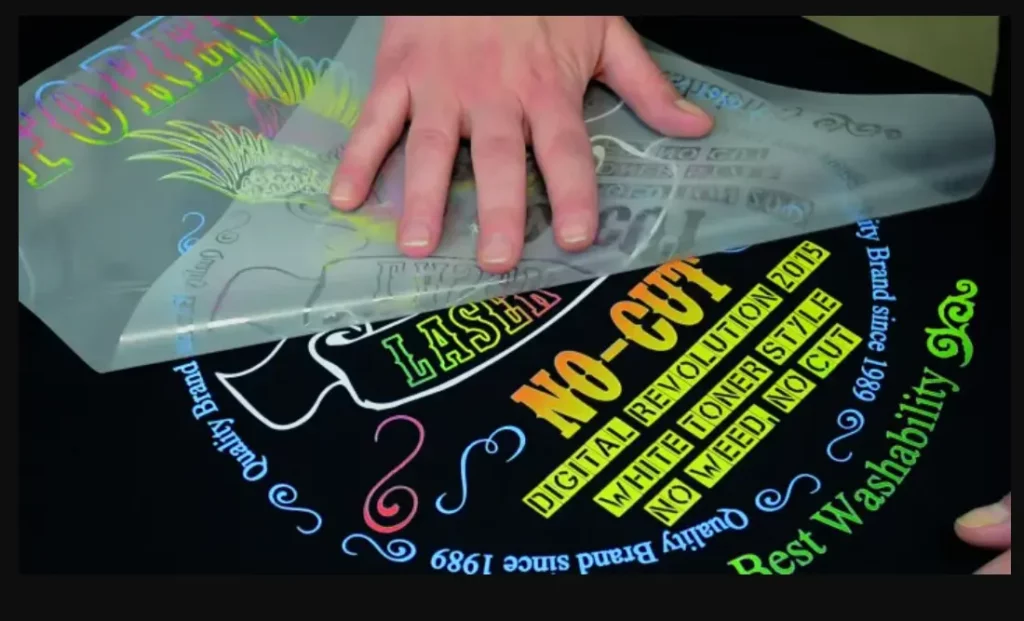

Heat exchange sheets that self-weed or don’t cut were suitable with laser printers and merely transmitted the final image, eliminating the need to slice or remove the backdrop.

The majority of papers with white or light-colored clothing are one-step processes, so the page that publishes already includes a sticky coating and is prepared to place on the T-shirt straight away. A more extensive layer of glue is needed since sheets for darker and more colorful clothing must be more impenetrable.

The sheets that you printed need to be covered, as well as the adhesive, which is provided on a separate sheet.

Iron On Transfer Paper: Heat transfer paper that doesn’t need cutting.

A terrific, inexpensive, and straightforward way to transfer a picture to fabric is with an iron-on transmission sheet. Publish the picture here on an iron-on transmission sheet, then use a soldering iron or perhaps an iron to push the image through into the substance you want to transfer it to.

Batik Institute

What qualities should you consider while picking the appropriate heat exchange document?

Take into account the following aspects before selecting the ideal heat transfer sheet for any creative project.

Printer

Verify the functionality of your printer.

- Printing devices with inkjet technology

Its most popular form of the home printer is an inkjet model.

- Print with sublimation ink

For printing with sublimation ink, a unique ink is used that does not liquefy. The ink is heated by the printer till it transforms into a gas and hardens on the paper. Sublimation ink machines provide more close-up pictures that are resistant to fading when combined with heat exchange material.

- Printers with lasers.

In-home use of laser printers is uncommon. These substantial devices are now more expensive than a basic inkjet printer and therefore are frequently used in business settings.

Transfer procedure

A produced picture from a heat exchange sheet can be transferred using one of two ways.

- Iron

When creating a few patterns for oneself or as presents for close friends and relatives, folks should consider using a standard home iron. To replicate the way, use temperature and pressure in accordance with the manufacturer’s directions.

- Heating press

For small businesses, industrial heat irons are a preferable option. These devices can uniformly apply temperature and pressure across a sizable area and are designed to work with heat exchange paper, resulting in products of a high caliber.

Size

- Paper

There are several sizes available for heat transfer sheets. Make careful you select the heat exchange sheet as suits your machine because some bigger sheets match only some machines.

- Project scope

When choosing a heat exchange sheet, keep the program’s size in mind. Always take measurements for your projects, verify the printer’s size limitations, and select heat exchange material that would fit your needs.

I Just Bought A Sewing Machine Now What? Answer.

Batik Institute

Utilization ease

It’s simple to utilize heat transfer sheets. To perfect the approach, it’s a brilliant idea should experiment on a piece of fabric. To use, make careful to understand the heat exchange sheet directions.

Versatility

You could want more adaptability than what ordinary heat transfer paper gives, based on the publishing task. In place of using heat, wet is applied to transfer sheet prints on the material using water, soap, and force from a crescent wrench. Among the best options for publishing on solid surfaces is this. The best heat transfer sheet for painting on cloth is still traditional.

Substance Opacity as well as color

When choosing the ideal heat exchange paper to suit the project’s requirements, consider the hue of the cloth.

- Paper for light transfers

On materials with a light hue, a soft transferring sheet can be used. Since light-transferring material is transparent, the costume’s fabric may be seen through it to produce the art’s lightest tones.

- Transfer paper that is dark

Printing on dark-colored cloth requires the use of a dark, raised surface. Since white doesn’t print with inkjet printers, the backdrop is opaque white, which is essential. Whenever you warm the newspaper, the picture appears on dark-colored cloth because the white set of the document moves to the material together with the paint.

No picture deterioration occurs when using the dark sheet on materials that are light in color. Since all textiles, irrespective of hue, may be utilized with a dark transferring sheet. It is the best choice.

Durability

Durable designs are created using the finest heat exchange sheet. To avoid the pattern from splitting and peeling, search for a heat exchange sheet that delivers quick, simple image transference while keeping a high degree of flexibility.

Lacking a slicer, how can heat transmissions be made? In stages.

Create a print-ready project file

The picture file can be downloaded to your PC. Download the contents by selecting the subfolder with the right click. Publish the PNG file. Add the picture to the application. Choose the size that you want for your photograph. Select “Make It.”

You must reflect on the mat if you want to avoid light-material impressions. The picture should transfer correctly if it is placed face down here on a t-shirt. Hit “next.”

Make the temperature difference in printing

Then select “Send to Printer.” Check that the bleed is turned off after choosing the printers. Then select Print. You may use scissors to cut the image out once it has been downloaded.

Just a tiny margin should be left all around the picture. Try to have the edges trimmed and softened to make them less prone to lift afterward. You are now prepared to press after cutting the area surrounding the image.

Transfer heat-pressed

The iron should now be heated up. It is always a good idea to utilize 340 F. The ability to press for more time will be based on how large the picture is.

You may take three minutes to complete a whole page. You will need about 90 seconds for just a half page. It takes around 45 seconds to complete a quarter page. Put the t-shirt on over any silicone pad or Pressing mats. You may place a mattress on over such ironing to compress. Just be careful to push firmly and firmly on a material.

For a short period of time, preheat the t-shirt to get rid of any moisture and creases. As soon as your t-shirt has cooled, place the picture on that with the color regarding the selected out. You may affix it firmly if you’d like by using hot tape. Push the design.

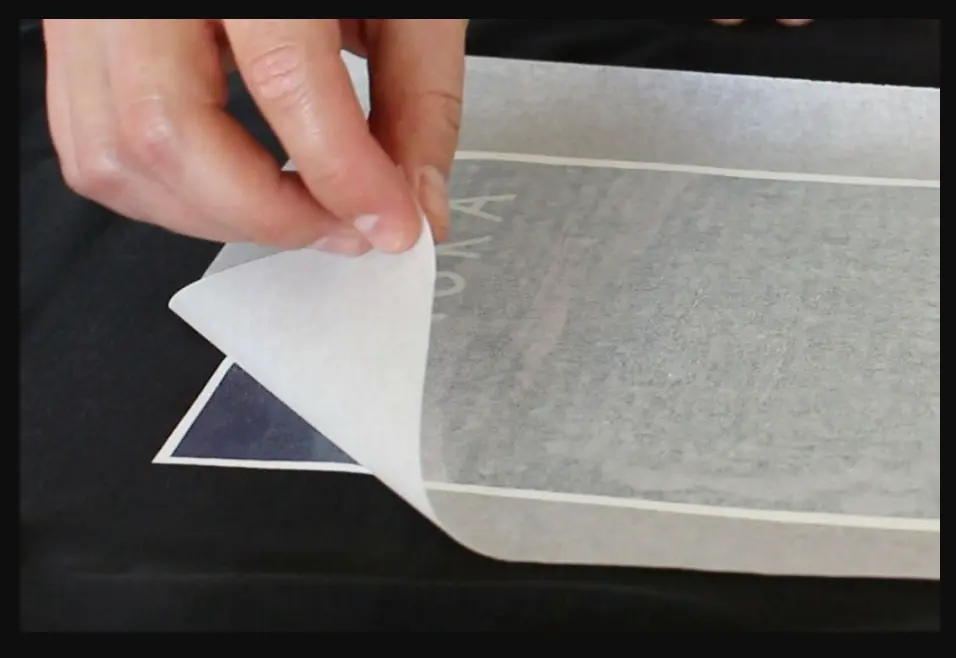

Prior to removing the covering paper, let it rest for a few minutes. Inspect to see if it has attached to the t-shirt adequately before cautiously peeling away the underlying sheet.

FAQ

Which sheets make the finest top heat exchange ones?

1. Iron-On Transfer Sheets from PPD.

2. Sublimation sheet A-SUB.

3. Printable T-shirt Transfers from Avery.

4. Inkjet Printing Transferring Sheets for NuFun Activities.

5. Paper for fabric transference called Koala Light.

6. Paper for inkjet transfers by Transfer Master.

7. Color-changing heat exchange sheet.

No cut printing: What is it?

A novel publishing technique called “no cut printing” uses double heads to produce a material that goes through with adhesives and warming chambers before chilling. This technique is comparable to big-format printing.