Some possible reasons and solutions for your DTF transfer might not stick properly includes:

| Reason | Solution |

| Not preparing the surface | Ensure proper preparation |

| Using low-quality DTF powder or ink | Use quality products |

| Problems in the printing process | Frequently check the printer |

| Problems with the base material | Choose the right base material |

| Environment issues | Create ideal environment |

Get the step-by-step pressing process for a successful solution for DTF transfer not sticking. Discover the detailed explanation with this article.

Key Takeaways

- Preparing the surface is vital for DTF transfers to stick effectively; use the suitable adhesive and follow manufacturer instructions.

- Using high-quality DTF powder and ink from trusted sources is essential to ensure proper adhesion and prevent printing issues.

- Selecting a suitable base material that is compatible with DTF transfers and preparing it can improve adherence and print quality.

- Maintaining an ideal environment with stable temperature and humidity is key to ensuring DTF transfers stick properly.

Reasons and Solutions for DTF Transfer Not Sticking

If your DTF Transfer is not sticking, it can be frustrating and costly, leading to poor-quality prints and wasted materials. By understanding the causes and applying these fixes, you can save time and money achieving high-quality prints with DTF Transfer.

Reason 1: Not preparing the surface properly

If you don’t prepare the surface properly, the ink or powder won’t stick well, and your transfer won’t work.

Common problems with preparing the surface include-

- not using enough adhesive,

- using the wrong glue for the surface, or

- not letting the glue dry before printing.

Sometimes, certain surfaces need more than one layer of glue or a different way of preparing them.

You can find the required products in your nearest shop or buy them online.

| Product | Feature |

| DTF PreTreat Transfer Powder | Works with all DTF & DTG printers |

Solution: Ensure proper preparation

To solve this problem,

- Make the surface clean and dry before you put on the glue.

- Don’t use too much or too little. Use the right type of glue and the right amount for the surface you’re working with.

- Also, follow the instructions from the manufacturer for preparing the surface.

Reason 2: Low-Quality DTF Powder Or Ink

DTF transfers might not work well if you use low-quality DTF powder or ink. The reason they don’t stick well is because they have uneven particle sizes. If the powders are old and past their expiration date, they can also make things worse resulting in bad prints.

Solution: Use Quality Products

To fix this issue,

- You should use high-quality DTF powders and inks.

- Make sure to buy them from reliable suppliers and check the expiration dates before using them.

- Regularly inspect the powders or inks to make sure they work well.

- If you find any that are low quality or expired, replace them. Follow the instructions from the manufacturer on how to store them for longer use.

Reason 3: Problems in The Printing Process

DTF transfers can be tricky as things like temperature, humidity, pressure, and setup can affect how the transfer sticks. If it’s too cold or dry, the glue might not work properly. And if there isn’t enough pressure, the transfer won’t stick well to the surface.

Solution: Frequently Check The Printer

To fix these issues, you should follow the instructions from the manufacturer. They mention the right settings for different temperatures, humidity, pressure, and how long to let it dry.

You might need to optimize your printer by converting and doing some trials to get the best stick.

Reason 4: Problems with The Base Material

A common problem with DTF transfers is not choosing the right base. Different materials can connect with DTF powder or ink in different ways because they have unique formulations. For instance, materials that have a rough or bumpy surface might not stick well with the transfer.

Solution: Choosing The Right Base Material

To fix this problem,

- It’s important to choose the right base material for your DTF transfer.

- You should research well and pick suitable materials that are known to work well with DTF Transfer.

- Check if they are clean and free from dust.

Reason 5: Environment Issues

Additionally, the environment- temperature and air supply can affect how well DTF Transfer sticks. For example, when it’s really hot, the sticky part can melt, and it won’t stick well. On the other hand, if it’s too cold, the part can dry out too much, and it won’t stick properly.

Solution: Creating The Ideal Environment

To make DTF Transfers stick well,

- It’s wise to adjust the printing conditions.

- The temperature should be right – not too high to avoid melting, and not too low to be drying.

- Humidity matters too; too little can dry out the adhesive, while too much can make it watery.

- Pressing with the required pressure during printing is important for the transfer to stick without problems.

- Lastly, follow the manufacturer’s instructions for the curing time.

- Transfer the stick properly before removing the backing sheet.

Tips to Press And Store DTF Transfer Properly

To make sure the DTF (Direct-to-Film) transfer sticks properly to the surface, there are several steps involved, which are-

- Before sticking a DTF transfer, prepare the surface right. Add a primer, coat it with adhesive, or use special solutions to make sure the transfer sticks well.

- Next, you need to print the DTF transfer. Make sure you use a compatible printer and the right DTF ink. Turn the picture around before you print it.

- Once it’s printed, cut out your design from the sheet. You can use a plotter or just regular scissors for this step.

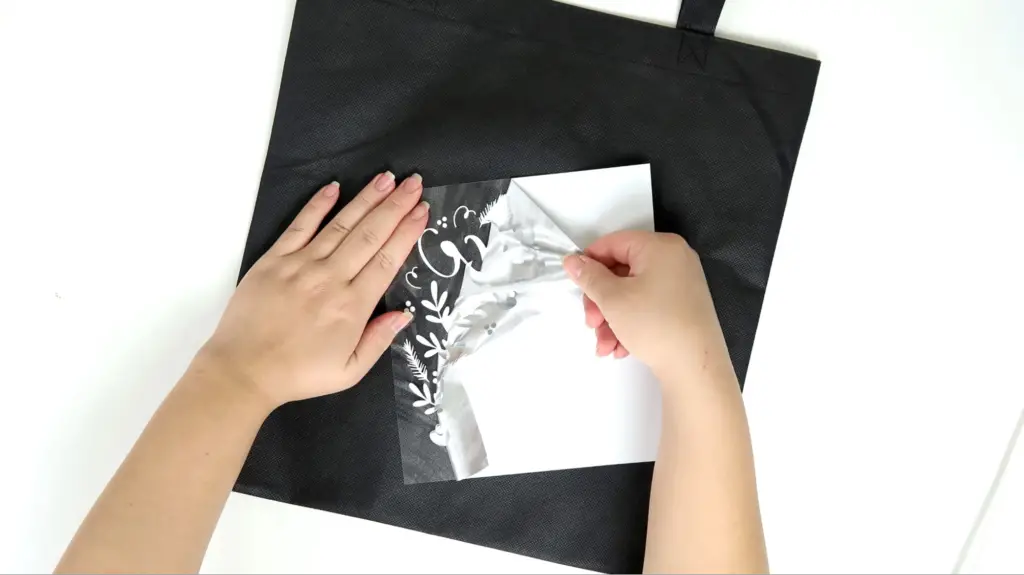

- Now, carefully place your transfer face down on the surface keeping it in the required position.

- To make the transfer stick, cover it with a Teflon sheet and use a heat press. You can even heat press Nylon bags but with different temperature settings. The temperature and pressure depend on the transfer type and surface you’re using.

- Usually, you’ll press it for 25-30 seconds at 320-340°F (160-170°C) with a pressure of 30-40 psi.

- After pressing, take off the Teflon sheet. While the transfer paper is still warm, gently peel it away from the surface. If some parts aren’t sticking well, you might need to press them again with more heat or pressure.

You can find the transfer paper in your nearest shop or buy them online.

| Product | Feature |

| DTF Transfer Film | Can be applied to all color fabrics |

Store DTF Transfer:

You can keep DTF transfers in good condition for up to 2 years by following these tips:

- Use quality DTF materials like film, ink, and powder to make the transfers. This way, they’ll stay colorful, soft, and easy to peel for a long time.

- Keep the transfers from sticking together by placing butcher’s paper or parchment paper between them. This paper also absorbs any moisture and helps keep the transfers dry and clean.

- Put them in a sealed container or a Ziplock bag with some silica satchels to keep them dry. This helps prevent humidity from getting to them.

- Don’t touch the printed transfer with your fingers, use gloves if you can. This prevents smudges or scratches that can make the transfer quality worse over time, even if you stored them correctly.

- Keep them in a place where the temperature and humidity won’t vary much. Big changes in the weather can make the colors fade or change over time.

Frequently Asked Questions (FAQs):

Why The Color Is Not Coming Out of The DTF Printer?

It could be because some safety caps on the ink tanks are closed. Also, there might be a lock that’s stopping the ink from flowing properly, or the initial ink setup didn’t work. To fix this, open a program called Resetter, then choose ‘Particular adjustment mode,’ and find the ‘Ink charge’ option. Press ‘OK’ to fix the problem.

How to Stop A DTF Printer from Smudging?

The printed design gets messed up when it touches the printer. So, to prevent a DTF printer from smudging, you can try letting the printout dry completely before handling it. Also, you can try adjusting the printer settings or using different printing materials to get a better result.

Why Is The DTF Transfer Not Lifting?

If the DTF transfer is not lifting properly, you should place a Teflon sheet on top of your item. Adjust your press to medium-heavy pressure. Wait for it to completely cool down. Then, carefully peel off the Teflon sheet.

Closing Words

Now you know the solution if your DTF transfer is not sticking.

By using good quality DTF, and picking the right material, you can master it. Also, it’s important to use the right amount of time, heat, and pressure when pressing.

You should always do some trial and error to figure out the best way for your DTF transfer.