The technique of applying a picture to the material of choice with silk screening is enjoyable and reasonably simple. This post will teach you ‘how does silk screening work!’

Quick Response

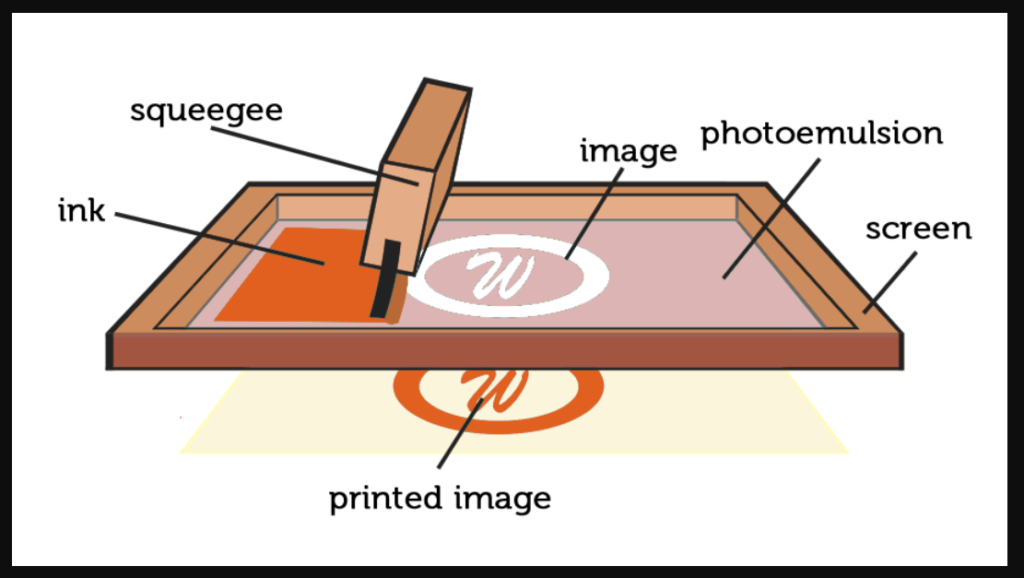

How does silk screening work? Over a piece of paper that would retain the image, the screening printer positions the printed framework and then drags ink over it. Its ink would then be pressed through into the display and onto below-screen paper. All the edition sheets are put through this procedure once again, and the stencil is removed and thrown away.

What does silk screening mean?

Serigraph is another name for silkscreen printing. Combining the terms seicos, which means silk, with graphos, which means writing, creates the term serigraph.

A permeable cloth mesh spread over a framework known as a screen supports stencils used in the silkscreen painting stenciling technique, which includes printing paint via stencils. For strong visual patterns, silkscreen painting is the perfect medium.

The past of silk screening

Stencils were employed initially to design Greek mosaics as well as Egyptian graves as early as 9000 BC, at which point silkscreen printing first appeared. China produced pictures of the Buddha between 22 and 618 AD using stencils.

By creating a complicated procedure in which a length of silk was spread along a framework to act as the carrier of manually cut patterns, Japanese artists transformed screen printing together into a sophisticated art form.

Within the fifteenth century, silkscreen printmaking reached Western civilization. Silk would be the first substance that screen printing was done on. Thus, silkscreen printing received its name. The preferred material today remains polyester.

Once a number of artists engaged in Government Art Installation explored both methods and later founded the National Serigraphic Association, screen printing inside the U. S. gained stature as an artistic medium.

The name “Serigraph,” used by American artists to differentiate artwork from industrial silk screening, was first used to describe “fine art” silk screening. Serigraphy gained popularity in the 1960s among POP painters, who were drawn to its flat-colored solid sections.

What advantages does screen printing offer?

It is wise to evaluate the various advantages of adopting screen printing technologies before making a decision. These are only a few of the advantages.

Flexibility

Printing technology has a variety of uses, which is one of its key benefits. It may be applied to virtually any material, including metal, plastics, wood, and glass. Furthermore, other hues can be employed. Screen printing allows for virtually unlimited creative flexibility.

Longevity

Screen printing may apply more ink than other printing techniques, producing a pattern that is more lasting. Furthermore, the specific coating, including chemicals, can render the paint resilient to UV radiation, abrasion, dampness, and toxins, enabling screen-printed items to be utilized outside and in challenging settings without deteriorating.

The dynamism of ink hues

It might be challenging to duplicate the more vivid and striking colors created by silk screening using other methods. Adding and removing are employed for designs with various colors, preserving the true brilliance of each hue.

Monetary efficient

Long-term cost-effectiveness favors screen printing. After setting everything up, printing products in large quantities is comparatively quick and straightforward. Therefore, it is acceptable to claim that the unit cost decreases as you create greater.

Excellent quickness and effectiveness

When one screening has already been made, screen printing is among the fastest and most effective printing methods. When the exact artwork is reproduced again, this is a fantastic solution.

Easy to follow procedure

Regardless of whether it is mechanized or performed manually, the overall screen printing procedure is pretty simple. Additionally, it is easy and inexpensive to replace the necessary tools.

How does silk screening work?

You begin with a square door frame approximately the size of a T-shirt when using the classic silk screening method. You firmly stretch a fine piece of cloth over this framework. That’s the display.

You place a thinner plastic cover over all this flimsy fabric and drill holes into that one where you would like the paint to emerge on the T-shirt will emerge. A fluid plastic covering that is reactive to UV irradiation may be used to “cut” tiny holes instead of using a scalpel by using light instead of a knife.

The screening is then pressed onto cloth while the T-shirt is still on a smooth surface. You may make ink run through into the screening and then onto the T-shirt by covering the panel with a generous amount of ink using only a swab. Iterate this process several times for patterns with numerous colors, working your way up from the weakest hue to the deepest.

The Best Resolution For Screen Printing

Batik Institute

Process of Silk Screening

Step 1: Apply paint to the display

An item of transparent cloth is utilized as the silk screening background. An emulsion that is detectable, like diazo photo fond, is first applied to the display. Following that, the display is allowed to cure in a location that is entirely dark and without lighting.

Step 2: Screen burning

A translucent plastic sheeting with drilled holes throughout it where the ink must emerge would then be placed close to illumination to burn the screening. Tape is used to fix the plastic cover into position. After that, lighting is shone upon the display to “burn” the photosensitive emulsified coating.

Step 3: Rinse

When the display is finished being burnt, the transparent plastic sheet gets removed, and the display is then gently cleaned with water. The picture will be entirely removed from the exposure that formerly contained it. The screen must then be gently placed aside to cure.

Step 4: Anchoring and poking the display with pins

The sturdy tape has to be used to fasten the display towards the printmaking frame. Its display then includes testing for any spots where the exposure might well have unintentionally been wiped off.

Well, with the help of some dark tape, seal off some of these washed-out tiny holes and stop the ink from leaking onto the regions that weren’t initially intended to be there. The display is currently prepared for the screen pressing.

Step 5: Printing

The first printing must be made once the screening has been carefully aligned and fastened towards the presses. The picture on display is entirely covered by the colored ink that has been applied. In order to guarantee that now the paint correctly passes through the display and into the substrate below, a scraper is employed to push and glide over the paint at a certain angle.

In the event that more than one hue of paint is required to create the final picture, the procedure is iterated. When going over the subsequent component, the initial print is examined for any screening positioning mistakes.

Step 6: Dry the ink

After the image has been created satisfactorily, the item is gently placed aside to allow the ink to dry or cure.

How to fix a sublimation mistake on a shirt?

Batik Institute

FAQs.

What are the drawbacks of silk screening?

Inefficient financially for lesser amounts. Using several hues in a design is indeed not cost-effective. Only when the design visuals are the same on every piece is it economically viable. Because silkscreen involves specific materials and skills, it can be challenging to perform.

What is the lifespan of a silkscreen?

When evaluating whether such printing will fade, dye clarity is quite important. Experienced printers that use quality ink would produce silkscreen painting that is resistant to fading and, therefore, can endure approximately 40 to 50 washing before beginning to show indications of wear.

A silk screen may be used how many times?

The stencils may be used repeatedly once the design has been burnt onto them, at which point they lose their shelf life. The stencils may be reused hundreds of times with appropriate maintenance!